Just recently we had G-Star released their ‘Most Sustainable Jeans’ collection and we now have Levi Strauss catching up the sustainable bandwagon and has come out with Project F.L.X – which they claim is the most sustainably washed denim.

Levi Strauss & Co. introduces Project F.L.X. (future-led execution), a new operating model that brings denim finishing into the digital era. By digitizing denim finish design and development, the company is enabling a more responsive and sustainable supply chain at an unparalleled scale. Project F.L.X. radically reduces time to market and eliminates thousands of chemical formulations from jeans finishing. Through Project F.L.X., the company is claiming is that they are achieving the ultimate balance of agility and sustainability, while upholding their standards of craftsmanship, quality and authenticity. LS&Co. has begun piloting Project F.L.X. with select vendors and retail partners and will roll it out across its supply chain in a phased approach over the next two years. The rollout of this new digital platform will be phased over time, with a goal of being fully scaled in 2020.

HOW ITS STARTED

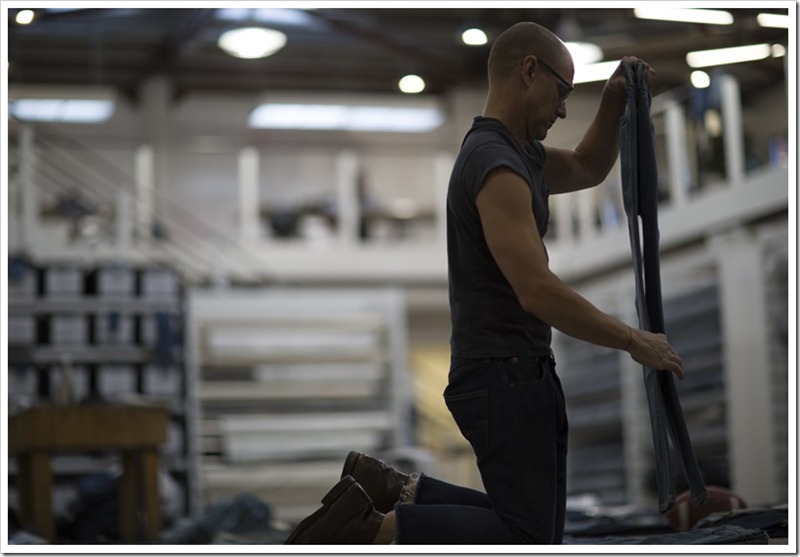

Project F.L.X. was built in-house at LS&Co.’s Eureka Innovation Lab by a team of designers, developers, chemists and engineers passionate about revolutionizing the apparel industry to better meet consumer needs while also doing right by the planet and the people who work in the apparel supply chain. A number of LS&Co. team members were retrained and reskilled in software development and laser operations. Retraining will be a key tenet as this new model rolls out globally. To help unlock the benefits of more sophisticated laser technology, LS&Co. turned to long-standing partner Jeanologia, a leader in eco-efficient solutions for fabric and garment finishing. Since 1993, Jeanologia operated with the ambition of advancing sustainable apparel manufacturing by delivering disruptive technologies, including ozone, laser and e-flow finishing systems. The company’s like-minded focus on scalability was essential to supporting LS&Co.’s end-to-end, transformative vision.

“We believe it is possible to be both agile and sustainable without compromising the authenticity our consumers expect from us,” said Chip Bergh, president and CEO of Levi Strauss & Co.

Four Major Developments Under Project F.L.X. :

1. Replace manual techniques and automate the time-consuming, labor-intensive and chemical-reliant process of hand-finishing: For more than 30 years, the apparel industry has used hand-finishing to accentuate worn, faded design elements on denim. By using lasers in new ways, finishing time is cut dramatically – from two to three pairs per hour to 90 seconds per garment, followed by a final wash cycle.

2. Create “photo-real” finished garments digitally: By digitizing the finish design and development process, LS&Co. designers can now create finishes and final garments with a revolutionary new imaging tool. Built by LS&Co., this advanced imaging capability cuts finishing design and development time in half (from months to weeks and sometimes days) and is so accurate the digital files can be sent directly to the vendor and quickly scaled to mass manufacturing.

3. Take advantage of on-demand and even hyper-local production capabilities: By delaying decisions on final products until much later in the process, LS&Co. can radically reduce its lead times from more than six months to as fast as weeks or days in some cases. This is made possible by staging garments that await their on-demand finish order closer to the market.

4. Eliminate thousands of chemical formulations from its supply chain: LS&Co. plans to reduce the total number of chemical formulations used in its finishing process from thousands to a few dozen. This is a major step forward in the company’s commitment to achieving zero discharge of hazardous chemicals by 2020 and furthers its goal of pioneering more sustainable apparel.

“With this new model, we can deliver the authentic and iconic products we’re known for in an incredibly responsive and responsible way,” said Liz O’Neill, senior vice president and chief supply chain officer for Levi Strauss & Co. “The advanced imaging capability is a game-changer for us, and something that has eluded our industry for years.”

“One of the biggest challenges we face as an industry is ensuring we have the right products at the right time as well as the ability to respond to our customers’ evolving needs with speed,” said Paige Thomas, Executive Vice President and General Merchandise Manager for Men’s and Kid’s at Nordstrom Inc. “The team at Levi’s is working towards this challenge by contributing to the future of the apparel industry as one that’s both agile and uncompromising on quality, while improving sustainability. We’re excited to be part of it.”

When we quickly compare the G-Star RFTPi jeans and the Levi’s F.L.X jeans, we find that there are differences among them in terms of scope of sustainability. While the G-Star jeans covers even the cotton aspect and the dyeing of the fabric and even covering the accessories, Levi’s jeans gets its sustainability score from the processes used in jeans finishing where they use the modern laser and other methods to achieve zero chemical and very less water usage . But our vote would go to G-Star as their scope seems wider and they have tried to cover the major inputs into the jeans rather than only covering the jeans finishing part.