As one of Turkey’s most established integrated textile companies, Bossa continues to lead in sustainable denim innovations through investments in advanced R&D, eco-focused technologies, and brand-driven development. Ahead of their participation in the upcoming Denimsandjeans Egypt edition (Jan 19 – 20, 2026), we spoke with the Bossa team to understand their latest developments, ongoing collaborations, and long-term vision for denim’s future.

Below is the interview shared by the Bossa team.

Annual Denim Fabric Production Capacity

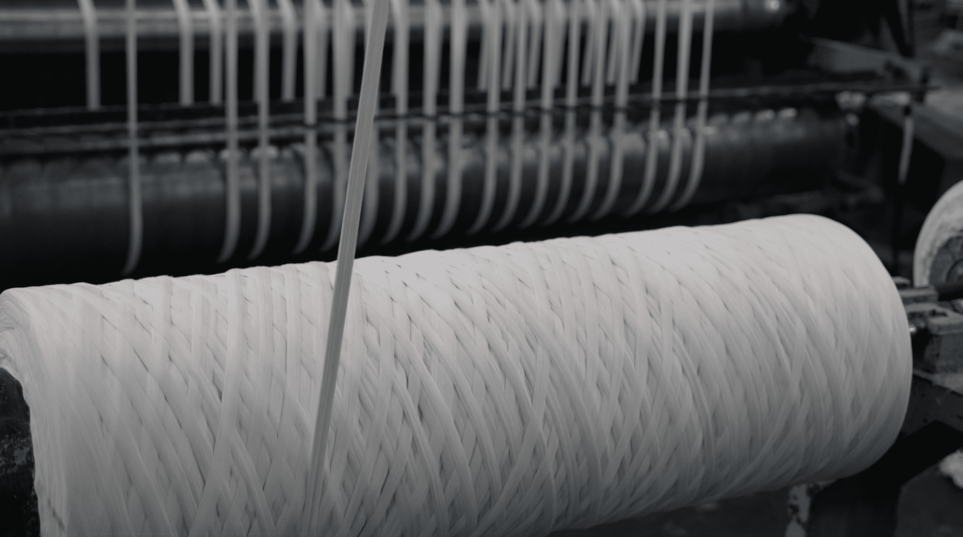

As one of Turkey’s largest integrated textile manufacturers, Bossa has an annual fabric production capacity of approximately 60 million meters. Additionally, Bossa has shifted toward higher value-added fabrics over the past decade. Although this has led to minor fluctuations in total meter-based output, continuous investments in technology and quality have significantly improved production efficiency.

How Bossa Has Evolved Over the Years?

Today, Bossa is positioned as an integrated facility capable of combining innovation, sustainability, and premium-level production at scale. The company has transformed into a textile technology enterprise that delivers brand-specific solutions by integrating performance, sustainability, aesthetics, and speed into its product development. Furthermore, this transformation integrates digitalization, traceability, and speed.

Collaboration with SaXcell and Circularity

Bossa collaborates with SaXcell, a regenerated cellulose fiber created through the chemical recycling of cotton-based waste. The process recovers high-quality fibers from used textiles and reduces the need for virgin cotton. When integrated into denim blends, SaXcell enables the development of Bossa’s “Endless Blue” concept, a fully circular product line. The team also carried out extensive R&D to improve fiber strength, homogeneity, and dyeing compatibility. As a result of these efforts, Bossa now achieves industrial-scale production while maintaining yarn durability and fabric quality in both pure and blended versions.

Digital Product Passport & QR Traceability

Alongside sustainability, Bossa prioritizes performance-driven fabrics, digital sampling, and advanced R&D. Bossa’s ongoing Digital Product Passport/QR system aims to share the following data on a product basis:

• Fiber content and origin

• Processing facilities (spinning – weaving – dyeing – finishing)

• Certifications (GOTS, ISO, etc.)

• Production batch details

• Product carbon footprint and recycling instructions

This system enhances transparency and trust between brands and end users while making sustainability claims verifiable.

Renewable Energy Investments

Bossa A.Ş. continuously expands its renewable energy investments to reinforce its commitment to responsible manufacturing. The company now covers all factory rooftops with solar panels, generating 17,700 kWp and supplying nearly 30% of its total energy demand, including land-based installations. In addition, new solar farm projects across Turkey will increase this share to 45% by the end of 2026. Bossa ultimately plans to reach 100% renewable energy usage by 2028, advancing its transition toward fully clean-energy production.

Participation in Denimsandjeans Egypt

Manufacturers and brands in Egypt closely follow global trends. Bossa’s sustainable, eco-friendly, and high-performance denim fabrics consistently attract strong interest, and similar engagement is expected this year. Our expectations for the growing Egypt fair include:

• Establishing a fast and efficient logistics and import route between Turkey and Egypt

• Exploring suitable conditions for fabric warehousing and stock programs, which we are actively researching and discussing.

The first D&J fair in Egypt was highly active and successful, and we believe it will continue to grow with increased customer participation.

Bossa’s 2030 Vision & R&D Focus

By 2030, Bossa will be a premium denim innovation center operating entirely on renewable energy, with full traceability and industrial-scale production of circular fiber blends.’

The projects that bring us closest to this vision include our collaboration with SaXcell (fiber circularity), the Digital Product Passport (traceability and transparency), and ongoing solar energy initiatives.

With a clear emphasis on circularity, renewable energy, and transparent supply chains, Bossa is aligning its strategy with the evolving needs of global denim buyers. As they join Denimsandjeans Egypt, their commitment to sustainable innovation and region-focused programs highlights their growing relevance in international markets.

Register here to attend Denimsandjeans Egypt Show.

Save Dates for Denimsandjeans (D&J) 2026

D&J Vietnam | D&J Egypt | D&J India