Sustainability is the capacity to maintain a certain process or state indefinitely. Sustainability has been expressed as meeting the needs of the present without compromising the ability of future generations to meet their own needs. With over 1800 gallons of water estimated to go into production of one jeans (from cotton growing stage) , sustainability is being taken seriously by some jeans manufacturers worldwide. One of such manufacturer is Crystal Apparel Group (HK) with operations in China and Vietnam.

Crystal Apparel Ltd (CAL) is one of the subsidiaries of Crystal Group focusing on denim garments, with its own facilities in Zhongshan and Jintan, PRC, serving markets of the United States, European and Asian countries.

With an outstanding global customer base, CAL caters to multiple brands that market their products across the world with an annual production of over 25 million pieces of garments and annual sales turnover more than HK$1.8 billion in 2011.

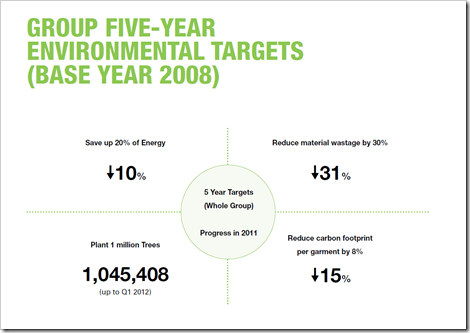

Crystal Group commits to be socially accountable to the world by improving its environmental performance. This is their second sustainability report which complies with the Global Reporting Initiative (GRI) G3.1 Guidelines and corresponding to level C (last report was published in 2010). This report relates to the denim jeans factory, Zhongshan Yida Apparel Ltd. (thereafter named Yida), located at Zhongshan, Guangdong Province, PRC, which is wholly owned by Crystal Apparel Ltd.

Crystal Apparel Ltd. is engaging in woven garment production, its subsidiary, Zhongshan Yida Apparel Ltd. is a denim garment specialist. Most people think the jeans production is a traditional industry, with high energy consumption and labour intensive. However, when Yida was setup in 2005, the group worked with innovative ideas in the operation, which includes their sustainability framework.

The ECO APPROACH

Energy Consumption

The nature of jeans production can be energy intensive, we value energy efficiency as an opportunity to reduce costs and emissions.

Carbon Intensity —Emission per Garment

In 2011, the performance of Yida was 2.657kg CO2e per garment, 22% less than in 2008.

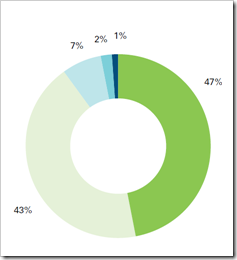

Energy usage by source

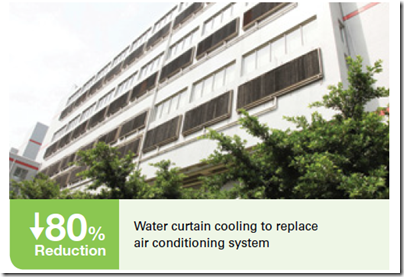

Different energy saving measures adopted to save electricity. Some of these were:

Water Consumption

“Water has become scarcer in the world. As part of our

effort to conserve water, we find ways to reduce the

fresh water consumed in production while enhancing

the reuse rate of treated wastewater. In 2011, the total

water consumption was 1,483,772 tons, in which 60%

is recycled water.â€

• Fresh water 40%

• Recycled water 60%

100% waste water was treated

• Recycled in production 70%

• Re-used for flushing and plantation 20%

Noise Management

In hydro-extraction, they replaced the traditional machine with high pressured squeezer, which produces no noise, and provides :

• Better working environment for workers

• 20 times greater efficiency than traditional extractors

As for power generators, sound isolation rooms and equipments were installed in order to eliminate the intensive noise levels from the machineries. Such isolation provides a better working environment for employees, as well as the neighbouring community

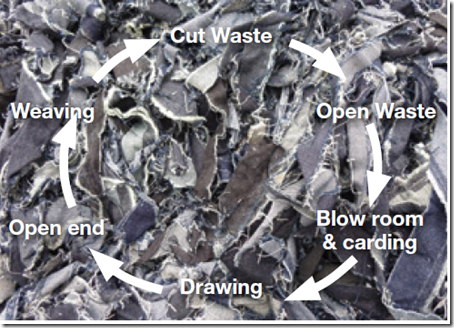

Up-Cycling – Recycled Cotton

Instead of depositing cotton fabric remnants into the landfills, CAL manufactures certain lines of denim with recycled material – cotton.

The initiation to recycle fabric remnants helps in upcycling the waste to a better extent while conserving natural resources including land, water and energy for the whole product life cycle. In 2011, they turned 774 tons of fabric remnants into recycle fabric (which was equivalent to reducing 774 tons of waste), and saved 968 tons of cotton a year.

Waste Recycling

CAL joins suppliers to recycle used products, such as chemical barrels,

thread cones, marker paper cones and printer cartridges.

Industry-Academia Research Partnership

The introduction of advanced technology, training and development,

optimize productivity and enhance product competiveness are Yida’s

strategic initiatives in industrial transformation and upgrading.

They now partnering with 4 institutions (WuYi University, GuangDong

Pharmaceutical University, DongHua University, University of Electronic

Science & Technology of China) to work on diverse projects, which include

production and environmental improvement, information technology,

human resources and product design.

Innvoative Technologies

Automated Rover System – The production units have been equipped with intelligent hanger system (Rover System), which improved productivity, reduced rework and defect rates and increased operators income.

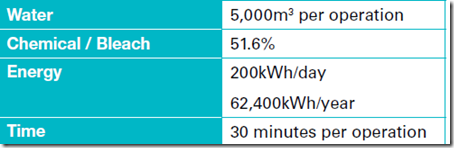

Washing Processes

The use of “Ozone Treatment†technology for waterless bleaching achieves no-water-no chemical washing process. It provides an eco-friendly finishing

to garments and denims to cut chemicals, and is said to be a finishing that is “washed by the atmosphereâ€. In Jun 2012, CAL successfully produced

zero-water eco-jeans for one of the most famous U.S. brand. The saving from replacing traditional bleaching with the above Waterless Bleaching is reflected here:

Environmental Awareness

CAL says

“We believe our employee engagement can make a difference

in our business and for the planet in which we live.We encourage employees to initiate activities that raised eco-awareness

within their working environment and their surrounding communities.â€

Sustainability would become an imperative in the coming years and would no longer be a fashion tag as manufacturing apparel like denim cause more environmental damage. Focus on sustainability would become necessary for larger companies initially with customers demanding sustainable process besides , of course , good price. But here is the contradiction – sustainable processes are never cheap and require investments which would need to be reflected in prices of the products.