What is the reason behind the increased focus for sustainability in textile products ? Lets look at some facts ..

- 7 Billion people in 2011 / 9 billion people by 2050. Feeding, clothing, and providing shelter for everyone does not come free. Everything has a cost. This cost has to be borne by the environment.

- According to textile exchange , about 20% of industrial fresh water pollution comes from textile treatment and dyeing.

- About 2700 liter of fresh water is used to make one cotton T-shirt. About 920 gallons to make one pair of Levi’s 501(and similarly for other jeans) . Other textile products also consume huge amounts of energy and water in processing and finishing.

- 1 Trillion kwh used by the global textile industry . This equals approx .10% of global carbon impact .

With this growing realization of need to have sustainable products and looking at this huge impact of textile industry on the environment – of which denim is an important segment – the natural way forward is only devising new products, ways and processes which can help in reducing the environmental footprint of textiles. A number of companies are contributing towards this end and we just interviewed Steffi Zhao of Primagreen (Danisco) to discuss their Flexible fading enzymes for denim which is a product in this domain contributing to reduced energy and water consumption.

Hi Steffi ! . Tell us a little about Flexible Fading for Denim from PrimaGreen®..

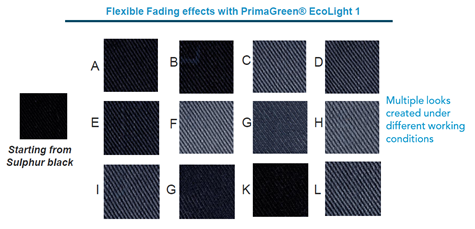

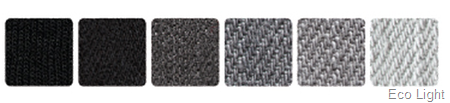

PrimaGreen® enzyme solutions from Genencor/DuPont are biodegradable, made from renewable resources, and manufactured using the latest biotechnology methods providing highest efficiency. The enzymes can replace corrosive chemicals such as caustic soda, potassium permanganate and hypochlorite. "Flexible Fading" for denim garments allows multiple looks on one basic denim fabric with PrimaGreen® EcoFade LT 100 laccase and PrimaGreen® EcoLight 1 esterase. Both solutions are more sustainable and controllable compared to traditional washing and deliver high-quality fabrics.

What is the difference between Traditional Denim processing and the processing done with Primagreen?

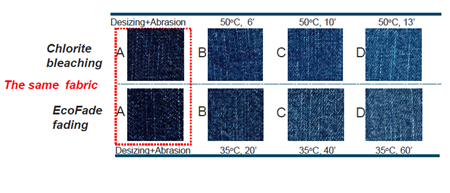

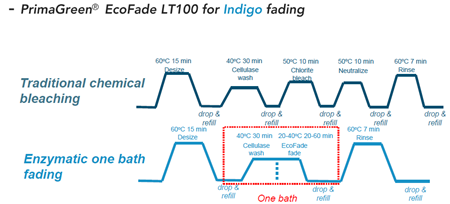

EcoFade LT 100 laccase is specific for Indigo fading while EcoLight 1 esterase technology fades sulphur black dyes. Compared to the traditional denim bleaching process, PrimaGreen® processing combines enzymatic denim abrasion followed by fading in a single bath with no drop and refill. These ready-to-use solutions provide excellent and reproducible effects in the fading of denim, -all at lower temperature and with less water. Meanwhile the enzymes allow designers to take one base denim fabric and create multiple looks with lowest fabric damage. That’s why we call this "Flexible Fading": Abrasion with IndiAge® cellulase and fading with PrimaGreen® laccase and esterase

The definition of ‘Environmental Friendly’ is sometimes vague. How can a denim mill be assured that they really contributing to the environment by changing their processes?

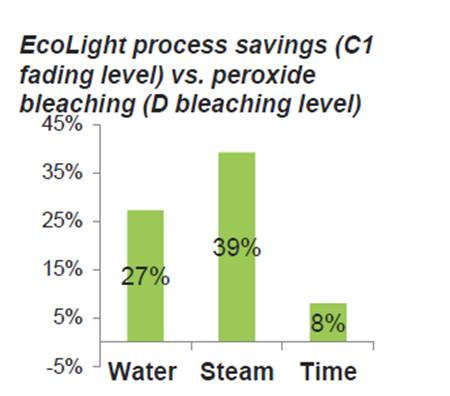

PrimaGreen® solutions provide significant, measurable reductions in environmental impact, including:

• Lower processing temperatures resulting in reduced energy use.

• Less fabric washing and rinsing resulting in reductions in water use and effluent.

• Decreased energy consumption resulting in reduced carbon dioxide (CO2) emissions.

These environmental benefits also allow for safer working conditions and reduce the total processing cost!

The final consumers- brands , retailers etc– are probably the most important in the value chain to help in awareness for environment friendly products. Do you think they are doing enough in this direction?

Pressure is growing to lessen the amount of water and energy used to produce textiles. The current approach is not sustainable given a world of finite fossil fuel resources and a growing carbon dioxide burden. There are always early adopters with the advent of any new technology and those that follow. It is often difficult to get companies to change a practice that they have been doing the same way for years or even decades. With the biotechnology resources we have at Genencor/DuPont we now have, within our reach, solutions to problems which we could not even imagine a few years ago. Fortunately, we see that brands and retailers take responsibility and look for more sustainable garment manufacturing practices. To do so, they need to fully understand these practices and this requires transparency within the total textiles supply chain. Initiatives such as "Textile Exchange", "RITE" and "Planet Textiles" allow direct communication between all involved stakeholders. As a positive result for us, garment brands are retailers are now starting to "prescribe" PrimaGreen® to the denim laundries, thus demanding more sustainable processing. Retailers that thrive in the future will feature the latest fashion looks produced with responsible processes; and consumers won’t tolerate anything less.

Black denim processing has , always , for various reasons not been the easiest. There are issues on color retention, rubbing fastness etc. How do you address these issues ?

One of the main issues we see with the traditional chemical fading of sulphur black fabrics is reproducibility, or the lack of it. Additionally, it is difficult to achieve an even effect on the whole garment; it’s too reactive and there is no control. With EcoLight 1 enzyme different aspects of the washing process can be adjusted such as: working time, temperature or application recipe. The milder -or more natural- processing conditions simply allow for more flexibility and highest reproducibility, resulting in the designed fading looks.

Reproducibility of effects on denim is a matter of great concern for processors and clients. How is the such consistency in fading effects created using your enzymes ?

Both PrimaGreen EcoFade and PrimaGreen EcoLight enzyme technologies provide reproducible fading effects, significantly reducing batch to batch color variations of treated garments. Our Textile Application experts around the world have conducted many trials, in our laboratories and in full scaled denim laundries, and optimized the washing processes with our customers. We have gained considerable experience with the products in different processing facilities with many different types of denim fabrics. And this type of collaboration-approach has become our approach to implement these new technologies, ensuring the best results. It’s a lot of work -preparing, conducting trials, evaluating- but the positive results are benefiting our customers and us!

Another important aspect is the processing of ‘Stretch Fabrics’ . The loss of stretchability in various processes is well known. It affects the life and the looks of the garment. Is it possible to have desired effects on stretch fabrics without affecting the elastane?

That’s the beauty of enzymes: they work in mild conditions and that is always a benefit to any type of fiber and fabric. Yes, our above mentioned Primagreen products allow you to get the desired effects on stretch denims without any damage when compared to chemical bleaching processes.

What is the ‘Single Bath System ‘ ?

It means the denim washing step with cellulase for abrasion and the step of enzymatic fading can be combined into one bath, thus saving water and energy. As part of our commitment to innovation, we continue to invest in developing and optimizing enzyme products and one of the many requirements is combined processing. We just launched a new neutral cellulase for denim abrasion: IndiAge® ONE. This is a super concentrated granular cellulase enzyme has a broad pH and temperature range and has the ability to attain high contrast and low backstaining on denim fabric upon formulation. It is the only enzyme you need to produce a wide range of denim abrasion looks in different working conditions.

What would you define as contribution to environment in terms of water and energy saved by the denim mills and garment processors using Primagreen ? Does it translate in any monetary savings for them as well ?

Due to single bath system and processing at low temperature compared to traditional chemical bleaching, PrimaGreen® "Flexible Fading" solutions can reduce water consumption and save energy. When working together with our customers we calculate the costs of the recipes, the use of water, effluent, and energy. Considering all these aspects, the benefit is cost reduction and therefore monetary savings for our customers. Of course this is a case-by-case evaluation, again emphasizing the need to work together with the brand, the retailer, the formulator and the laundry to find the best solutions.

To contact Primagreen – click here