It won’t be an exaggeration to say that sustainability is the future of not only our industry but also that of others and world in general. We , as a generation, cannot afford to be lackadaisical about our responsibility towards our planet as “we have borrowed it from our future generations” . Each of us today has a responsibility to do the whatever little bit we can do to ensure that we contribute our 10 cents in reducing the impact on our environment. This is not only restricted to our business activities but also to our personal lives. We really need to bring focus on what we need to do , what good things are being done in this direction and whatever we can hope to do. As Denimsandjeans,com, we will try to bring increased awareness to this aspect which is becoming most important in our lives.

As a starter, we are bringing together information about various sustainability efforts of our exhibitors who have been working hard to bring make their products and activities more sustainable and helping their partners as well in doing so.

For the starters, we focus on our industry and identify areas where the efforts are most crucial. Some of them are :  Water Saving, ZDHC , Renewable Energy, Sustainable Raw Materials, Waste Recycling , CO2 Emission Control, Circular Fashion. In this article , we gonna feature ORTA ANADOLU from Turkey, and KEMIN- GARMON from US/Italy and will highlight their efforts in this direction.

ORTA ANADOLU

Since its inception, ORTA has been weaving a denim heritage passed from generation to generation. Founded in 1953, ORTA transformed from a spinning and weaving company to a denim manufacturer in 1985. Today, ORTA produces over 60 million meters of denim in its Turkey and Bahrain factories and is creating a platform for leading manufacturers to step up and reclaim a denim industry where more aesthetics leads to more ethics.

ORTA started its sustainability journey at the beginning of 2000 by using organic cotton. The sustainability platform Orta is known as Orta Blu which was founded in 2010. As an early supporter and adopter of BCI, ORTA has always been on the forefront of sustainable change.

Today, Orta claims that

“While our footprint is what we take from the planet when we consume, our handprint is what we give the planet when we create change for the betterâ€. At Orta, We are on a mission to drive the denim industry into a more sustainable future. That’s why Orta Blu is in everything we do, at the intersection of where people, planet and purpose matter.

Beauty is in the process. ORTA is on a mission to create the most mindful, purposeful, sustainable and beautiful fabrics. ORTA’s technologists and developers have perfected the most advanced processes on the planet that yield superior quality fibers, recollect and re-life significantly reduce water usage and conserve energy. Our goal is to create next generation denim processes for a more beautiful and sustainable world.

On energy side, in 2015 Orta partnered with GDRE (General Directorate of Renewable Energy in Turkey), UNIDO (UN Indistrial Development Organization) and UNDP (UN Development Programme) to increase energy efficiency in the industry. With this collaboration Orta established an Energy Management Team that has been dedicatedly working on performance tracking, targets and projects since 2015, integrating energy management in all efforts since then. Another outcome of this collaboration is the establishment of ISO 50001 Energy Management System in their production plant, through which the company claims to save 11,7 GWh energy and to prevent the emission of 3,4 gigatonnes of greenhouse gas from 2015 to 2016.

With SS19, ORTA is making a bold commitment to be a leader in transforming the denim industry with the most advanced natural technologies. As of this SS19 collection and moving forward, every fabric will be made using the INDIGO FLOW process that is proprietary to ORTA. INDIGO FLOW is a CLEAN LABEL PROCESS where it is possible to achieve up to 70% reduced water use, better dye penetration, energy saving and get a fabric with richer and cleaner look.

“Embedding INDIGO FLOW into our manufacturing standards is our first step towards disrupting the denim industry and leapfrogging us to a Denim 4.0!”

One of the latest developments on material side is Zeromax Denim Family. It’s soft denim with shaping stretch that drapes next-to-skin. It has zero cotton and maximum soft shape. Zero max is woven with minimum impact to shape the future of denim and crafted with unique twill and elasticity fusion. Zero impact due to no use of cotton which contributes to environmental pollution through use of water, pesticides and chemicals in its production process.

With all the sophisticated new digital technology out there, there is a call to be more transparent in the manufacturing process. Orta took a step ahead to become more transparent through the Life Cycle Assessment (LCA) . LCA is an analysis method where the potential environmental impact of products can be assessed in each and every step along the life cycle from cradle to grave. With LCA, the company simulates production into a software by using its own facilities’ consumption, production and emissions as primary data combined with the secondary data acquired from the worldly known databases.

As of AW19/20 collection, Orta has labeled each and every ORTA garment with a unique QR Code that provides full transparency in the making of the fabric so that one can monitor and measure the environmental impact of their fabrics. In order to take their LCA studies one step further, they have also acquired the environmental product declaration (EPD) for 4 products. EPD is a 3rd party verification of LCA studies which provides transparency, credibility, and comparable information. The EPDs can be seen accessed from the International EPD System website.

Orta has also partnered with Alliance for Responsible Denim (ARD) from the very beginning. The ARD is an Amsterdam based initiative led by Amsterdam University of Applied Sciences, Circle Economy, Made by and House of Denim and brings together a collective denim brands to work together to make denim more sustainable.

ORTA and Circle Economy have been partners since 2016. ORTA assumed the primary sponsorship of a special event BEYOND GREEN that is brought out by Circle Economy and The Amsterdam Fashion Institute to create a circular fashion world. By using the collective power of students and industry to tackle critical issues throughout the fashion system, Beyond Green brings together new and established minds to push the boundaries of what we know, and realize what we dare to imagine. The company has also expanded their partnership with a project called Circle Fashion Tool, a decision making tool built to help brands evaluate the end of life options and circular opportunities for their own textile excess and weigh the practical implications and environmental and economic impacts between scenarios. The tool aims to empower brands to move from the ‘why’ to the ‘how’ of circular fashion.

KEMIN-GARMON

Since its birth in 1982, Garmon Chemicals established itself at the very center of a narrative that talks about innovative chemical auxiliaries and solutions. For over 30 years, Garmon Chemicals has been an R&D and marketing platform for fashion innovation and a reference for product quality and responsible practices. Last year , the company has been taken over by KEMIN group. Garmon has been known for its consistent approach towards developing new products to ensure the absolute sustainability .

Nimbus

As per Garmon

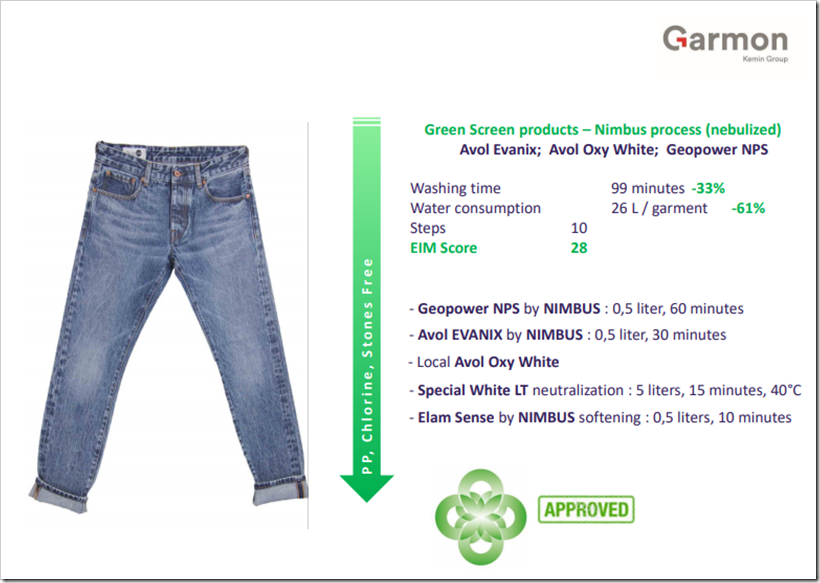

nimbus is the first ever range of chemical auxiliaries and dyes specifically selected to be nebulized in closed systems. nimbus chemistry allows for tremendous energy and water savings (up to 80%). Furthermore, nimbus chemistry delivers enhanced viscosity and fluid dynamics of the formulations selected for nebulization. This translates into more efficient contact and reaction between active principles and fibers, as well as an optimization of the chemical consumption. nimbus-z is the 3rd revolutionary wave in garments stone washing, which takes us from solid and liquid age to nebulization age.

GreenScreen

GreenScreen Certified™ builds on GreenScreen® for Safer Chemicals, the globally recognized tool for chemical hazard assessment that encourages the design and use of inherently safer chemical ingredients. GreenScreen Certified™ is owned by the NGO Clean Production Action (CPA) and Garmon Chemicals is the first one to introduce this certification to the apparel industry. GreenScreen Certified™ is what ZDHC (Zero Discharge of Hazardous Chemicals) recommends as one of the best tools to assess the safety of chemicals and one of the tools of their Chemical Gateway.

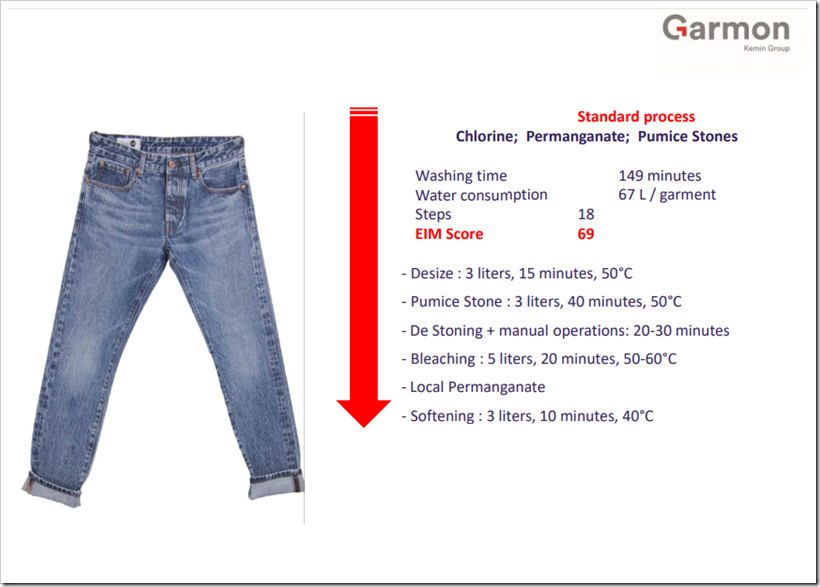

A EIM comparison score of results using Garmon’s green products

In the part II , we’’ll bring some more companies and tell you what are their efforts towards sustainability . For the latest updates , you can follow us on Facebook , Linkedin and Instagram