Isko , the company with the largest denim capacity worldwide , recently held a washing seminar at Istanbul . As a part of its knowledge sharing drive , Isko launches a number of washing seminars around the globe inviting different players in the denim supply chain from chemical suppliers, brands, retailers and many others. I too attended the seminar at Istanbul having been kindly invited by the Isko team . It was actually a very enjoyable experience to interact with the charged Isko team who were on a high on a great performance in

Isko , the company with the largest denim capacity worldwide , recently held a washing seminar at Istanbul . As a part of its knowledge sharing drive , Isko launches a number of washing seminars around the globe inviting different players in the denim supply chain from chemical suppliers, brands, retailers and many others. I too attended the seminar at Istanbul having been kindly invited by the Isko team . It was actually a very enjoyable experience to interact with the charged Isko team who were on a high on a great performance in  2012 despite global slowdown and also with a number of denim people from different parts of the world including brands like Topshop, Pull and Bear, Inditex, Mih Jeans, Les Temps des Crises , Chasin Score Mac Jeans and many others. It was a pleasure to see competing brands coming together to participate in an educative seminar .

2012 despite global slowdown and also with a number of denim people from different parts of the world including brands like Topshop, Pull and Bear, Inditex, Mih Jeans, Les Temps des Crises , Chasin Score Mac Jeans and many others. It was a pleasure to see competing brands coming together to participate in an educative seminar .

The first part of the seminar was held at DenimPA – in a vintage aesthetics showroom for denim . Marco Lucietti – the marketing and brand director of Isko laid out the tone for the day describing Isko’s the need for organizing such interactive seminars where knowledge on denim is shared across value chain. Marco also laid out the objective of Isko ISKO to be recognized as the BEST INGREDIENT BRAND for denim fabrics globally, like ingredient brand Lycra in fibres and Intel for computers.

Sessions were taken by top Isko R&D executives like Hamit Yenici and Moreno De Angelis to educate the participants about the various intricacies of stretch fabrics , on Fit and Design by Umberto Brochetto (Creative Room ) etc. Besides Nuria Estape from Clariant made some interesting presentations on Eco Processes of denim dyeing. The team showed some interesting new developments in fabrics and finishing. Particularly interesting to note was the new technology of a new replacement of sandblasting method – the Ice Blasting – which involves blasting the garment with Dry Ice (CO2) instead of sand. Its a very new concept and only a few laundries in the world can handle it. The participants were also keen to know about Iskoteca – the library with over 20,000 garments that Isko has in Italy and which enables customers to go through a vast depository of denim garments in different washes from around the world .

The afternoon session was the most interesting where the participants were taken to a unit of Baykanlar – a large garment unit from Turkey manufacturing about 6 million garments/year and supplying to major denim brands and retailers in EU . Besides an introduction of the unit, it was cool to see a catwalk with Baykanlar Collection made from Isko fabrics. Some of the interesting fabrics – like Reform (from Isko) – could be seen on young women and it was particularly noticeable that the women did look slimmer in this particular fabric – ratifying a claim often made by Isko. Of course, this fabric has been used by a number of top brands for this particular functionality. Loomfx was an interesting fabric for men which retained the aesthetics of a raw denim look inspite of being a comfort stretch fabric.

The visit to all the operations of Baykanlar unit was educative and interesting – specially the dry processing part. However, we were in for a surprise when suddenly we were brought into a room with dry processing machines and were divided into two groups – the DENIM

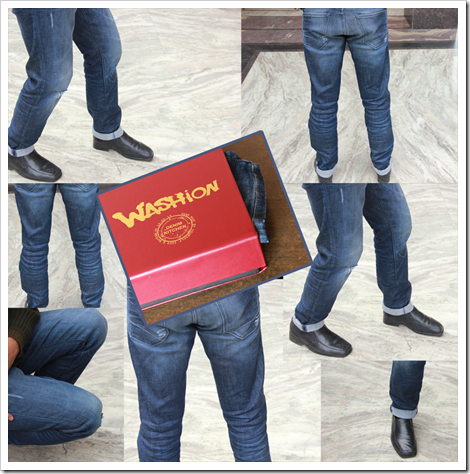

The visit to all the operations of Baykanlar unit was educative and interesting – specially the dry processing part. However, we were in for a surprise when suddenly we were brought into a room with dry processing machines and were divided into two groups – the DENIM  KITCHEN . Each of the groups was shown a WASHED Jeans and we had to replicate the looks on a raw jeans . Each one of us was given a raw jean on which we applied resin , created whiskers, applied PP spray and then hand sanded the jeans .. It was fun and created competitive spirit among the participants to bring out the best jeans !!

KITCHEN . Each of the groups was shown a WASHED Jeans and we had to replicate the looks on a raw jeans . Each one of us was given a raw jean on which we applied resin , created whiskers, applied PP spray and then hand sanded the jeans .. It was fun and created competitive spirit among the participants to bring out the best jeans !!

I should not forget to mention the great party at the end of the day – where we had fun with Isko, Baykanlar teams . However, the biggest surprise of the day was when we were presented with SAME JEANS that we had created with our own hands. It was just a plain good feeling to look at your own creation . And of course, my jeans were probably washed the best (or at least I think so ) .I am sure the quality of washing of my jeans entitles me to a few job offers from Denim Washing Plants !! .

One question, though , still remains to be answered. No one asked the participants their waist size and length and still got perfect size jeans(at least myself ) on which they had worked..Don’t know how Isko/Baykanlar team managed this . Need to ask them the secret sometime ..

Thanks to Isko team for organizing a great Seminar ….

We have created some videos from the show which can be seen below (only those who view this article online can see it ).